As we know it, Aluminum is categorized in the Group II of metals, which means it can easily lose electrons. Therefore it can be combined easily with other elements to form an alloy. When combusted with oxygen, aluminum forms an extra layer of oxidation (Magnesium Oxide) that gives the metal some layer to prevent it against corroding, rusting and even abrasion.

Group II metals have high electrical and thermal conductivity. Hence this it a good material for heat conductors and electricity conduction in CNC machining apparatus.

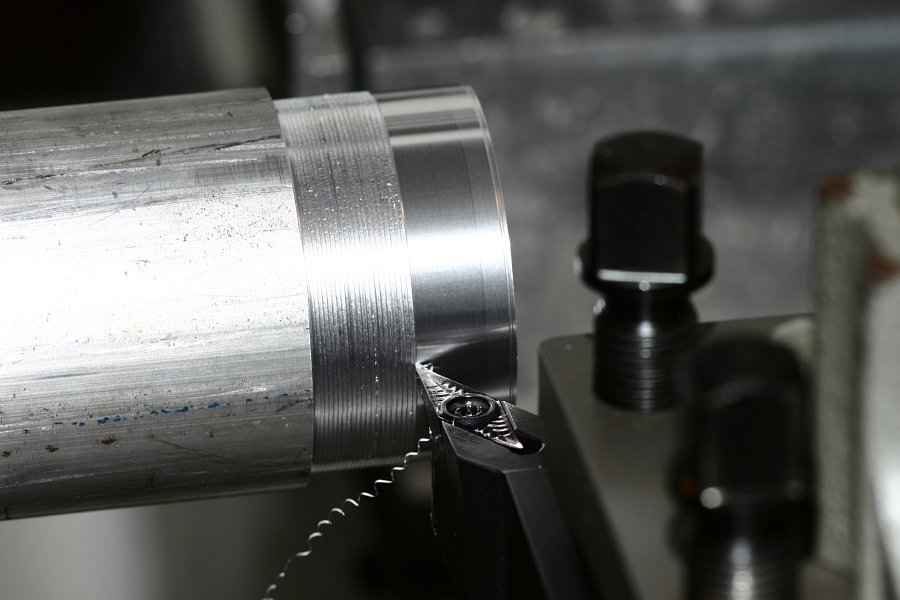

For Aluminum CNC machining, there are a number of factors that should be looked into. Because of the sensitivity of it, high speeds should be used when cutting so as to prevent cracking or damage of any kind. Aluminum cuts can be more extensive than stainless steel so cuts should be deep enough to prevent the tool from slipping on the surface. You should use sharp tools every time and in case of a sign of wearing out, replace them. When using Aluminium, you should always maintain a high cutting rate and never back from intensity unless it starts to wear. If it starts to wear, sharp objects are advisable to replace with since dull objects make it hard to bore the metallic surface. As friction will always occur, lubrication is important to cool the heat that the cutting goes out.

Aluminium CNC machining is used for products that require light materials. Some of these could be:

- Aircraft equipment

- House appliances especially those that use heat or electric

conductivity - Cables and engine blades